Restoration of a Breitling Sprint Ref 2016 composite case

Angelus Chronodato: a “cult” watch among vintage fans (Part 2/2)

24 December 2018

Vintage watches… to use them or to look at them?

11 February 2019“The case of this Breitling is from Fiberglass. The Breitling Sprint 2016 is a model of which few units were made, so finding a loose case in optimal conditions is nothing short of impossible. The one in my copy was broken so I went years behind one without success. One day through a mutual friend, I contacted Toni, an industrial engineer from a composite design and fabrication company focused on the nautical and aeronautical sector. Here we present to the readers of our BLOG the result of the brilliant restoration. Thanks Toni “”

WRITTEN BY

TONI GONZÁLEZ SALINAS

RESTORATION CASE FIBERGLASS BREITLING SPRINT REF 2016

The first thing will be to disassemble caliber and sphere, leaving only the monoblock case of composite material to be able to work in it without risk. This fiberglass case is manufactured like the majority that assembled the watchmaking firms at the time, based on a composite material, formed by a resin (usually epoxy) with a series of additives in charge of giving it the hardness, resistance, possibility of machining, etc to the case.

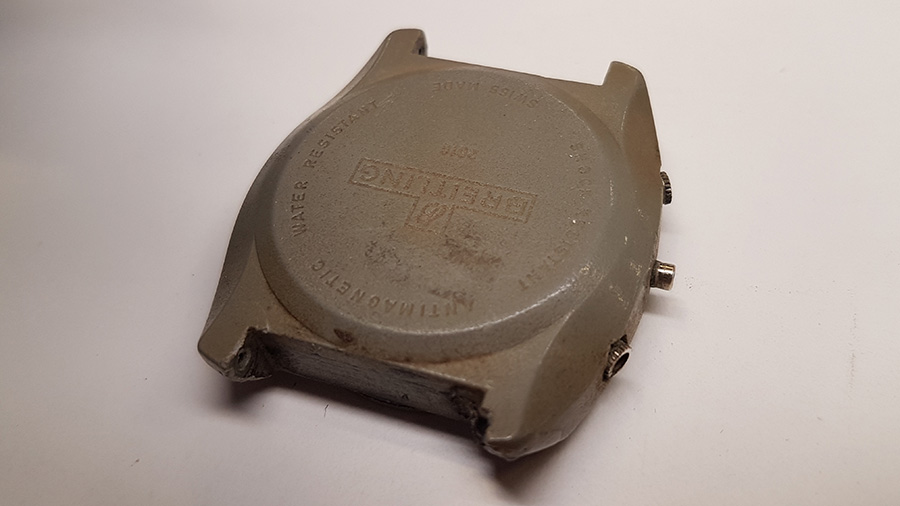

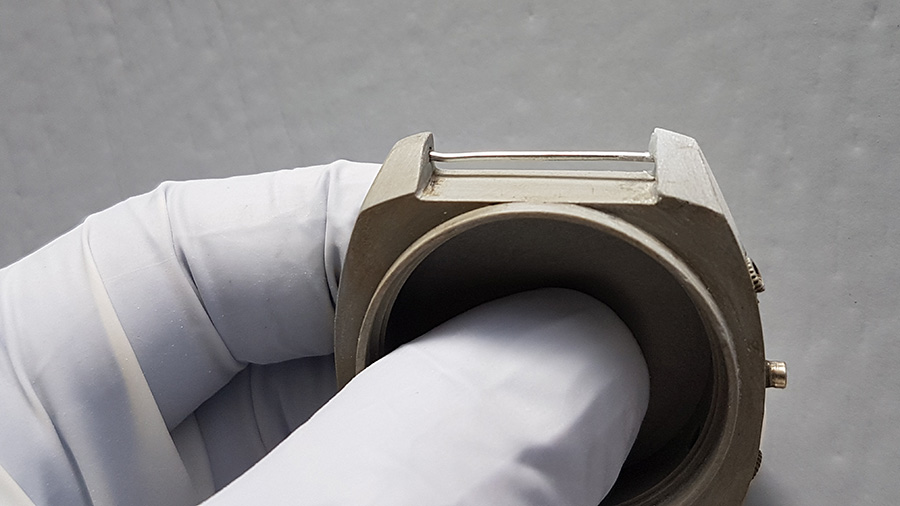

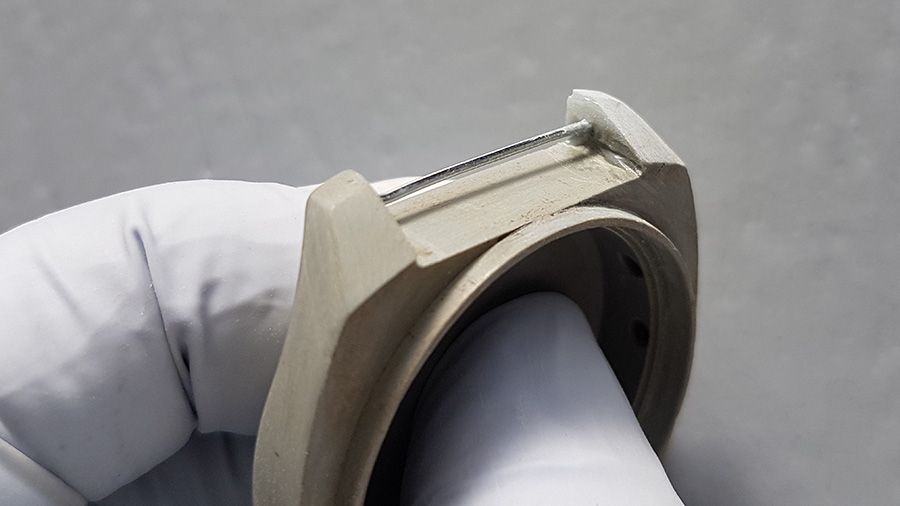

The following photographs show the state of the case, with one of the broken claws and a series of repair attempts that probably never came to fruition. You can also see the color of the case material, darker and brown tones, due to the passage of time and being in contact with the skin. Inside the case you can see the original color of it.

Before proceeding to recover the claw, we must clean the area, and due to the dirt of the case, we proceed to clean it with alcohol and give a smooth sanding to the entire case based on 400 grit sandpaper. We obtain the following result .

Next we will build a tool with wire of the same thickness to the pin of the belt, to be able to maintain the hole in its position and aligned with the hole of the opposite claw. For its subsequent removal, it must be impregnated with release wax.

Here it can be seen mounted.

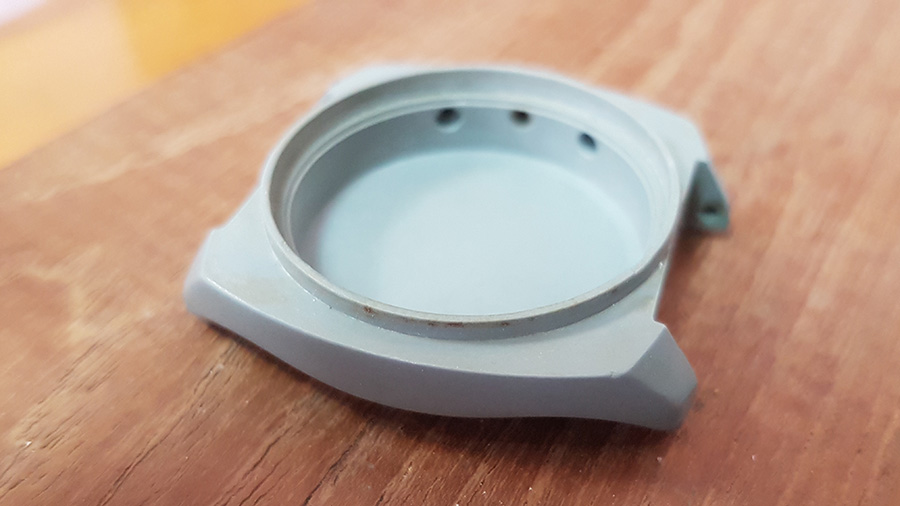

In order to reconstruct the claw, we must use the same material with which the case is built, that is, epoxy resin and additives. In this case, it has been used as additives silica and a ceramic charge, which in addition to increasing the hardness of the repair, gives it that gray tone similar to that of the original case. The gray tone is intended to be lighter than that of the case, since over time it will always darken.

Once 12 hours have elapsed, the resin is completely dry and it is now possible to sand the repair giving it a symmetrical shape to that of the other claw.

Finally we will have to remove the wire that made us the axis function and finish cleaning the case recovering its original color, which hides under that surface brown layer. We will use sandpaper of different grains and we will finish the process giving it a general polish with car body polish, also indicated for this type of materials.

The result is shown below, very different from how we received it.

And here with the watch mounted.